The hardness of a material is measured against the scale by. The three most common scales used for plastics are Rockwell E M and R.

Mohs Hardness Scale Harness Of Glass Screen Protectors Mohs Hardness 1 Victorcellular

This corresponds to four to six on a Mohs scale where a large amount of the useful industrial minerals exist.

Plastic mohs scale. Reconstructive procedures are performed on an individualized basis. Steatite Soapstone 1 - 25. MOHS micrographic surgery is a procedure that is performed by dermatologists with advanced training in the removal of certain skin cancers.

Plastic hardness qualifies the resistance to penetration of a plastic by a harder body. Soda Sodium bicarbonate 25. Mohs micrographic surgery MMS is widely used in North America and in Europe for treatment of BCC.

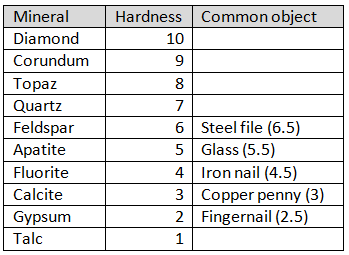

To use an example one of the hardest substances on earth diamond is rated 10 on the Mohs scale while plastic and pencil lead for instance are on the other end of the scale with a hardness grade of 1. The MOHS scale was created by trying to scratch one mineral with another and then recording which mineral left a scratch. Other Rockwell hardness scales are used for metals with Rockwell A B and C being the.

Mohs came up with a main list of ten natural minerals to show their hardness and scratch resistance to each other. For example a material with a Shore hardness of 95A is also a Shore 50D. As a Facial Plastic and Reconstructive Surgeon.

The Mohs Scale was developed in 1812 by a German mineralogist named Friedrich Mohs. The harder material wears or scratches the softer material. Its a key engineering parameter for constructing devices consumer products or industrial parts.

The three most common scales used for plastics are Rockwell E Rockwell M and Rockwell R. Summary In summary of this set Amazon link it is most useful for applications that involve minerals with industrial use such as iron or even man-made materials like concrete. Acrylic Type V approximately 35 on the Mohs scale Size ranges Plastic blast media is sized in ranges due to the random nature of the shape and sizing.

TPEs can range from 10 Shore 00 up to 72 Shore D spanning all three hardness scales however. The most common scale for this qualitative test is Mohs scale which is used in mineralogy. It loses 309 of its mass as water vapor on heating above 450C.

Mohs surgery is often closed by a reconstructive or plastic surgeon to lessen the impact of the surgical scar. As you can see from the graphic there is overlap on the different scales. The notes should also contain the location number and size of the lesions the number of stages performed and the number of specimens per stage.

While most of these items on the list are in somewhat of a relative order the last one diamond is an exception. Reconstruction after Mohs surgery at Osborne Head Neck Institute can often be performed the same day or the day after the removal procedure. The test is useful because most specimens of a given mineral are very close to the same hardness.

Due to the microscopic nature of the procedure Mohs surgery is not only better at removing the tiny cancer cells that escape other techniques. While this surgery is a highly specialized option to treat skin cancer it is most important that you discuss the advantages and disadvantages specific to your case with your health care professional before making a treatment choice. Conclusion This largescale retrospective study.

The shore D hardness scale measures the hardness of hard rubbers semi-rigid plastics and hard plastics. Fortunately plastic surgery can be performed to repair the wound and restore your skin to a more healthy and natural appearance. Scratch hardness is the measure of how resistant a sample is to permanent plastic deformation due to friction from a sharp object.

The Mohs Scale of Hardness for Metals. Scratch hardness is the measure of how resistant a sample is to permanent plastic deformation due to friction from a sharp object. The Rockwell hardness scales use different size steel balls and different loads.

Mohs hardness is defined by how well a substance will resist scratching by another substance. After the cancer is completely removed the resultant defect often requires reconstruction to restore a natural appearance by a fellowship trained surgeon. Rockwell Hardness Testing Conditions.

It is rough measure of the resistance of a smooth surface to scratching or abrasion expressed in terms of a scale devised 1812 by the German mineralogist Friedrich Mohs. The Shore D Scale measures very hard rubbers semi-rigid and rigid plastics PVC pipe for example. This test compares the resistance of a mineral to being scratched by ten reference minerals known as the Mohs Hardness Scale see table at left.

The Rockwell testing procedures used in the Plastic Industry are ASTM D785 and ISO2039-2. What is Mohs Hardness Scale. It is a white to off-white crystalline powder with a specific gravity of 24 and a Mohs hardness of around 30.

And plastic surgeons P. Mohs micrographic surgery was performed using accepted Mohs technique with the physician performing both the surgical and pathology services. RC 42 - 62.

Mohs microsurgery is a surgical technique that can treat common forms of skin cancer basal cell and squamous cell carcinomasthe commonest types and is one of the most effective treatments available. One of the most important tests for identifying mineral specimens is the Mohs Hardness Test. The Mohs scale of mineral hardness is based on the ability of one natural sample of mineral to scratch another mineral visibly.

It loses 309 of its mass as water vapor on heating above 450C. Sizing is typically based upon US screen sizes. 8 or RC 42 - 50.

Fro example Corundum Sapphire and Ruby was used to scratch ApatiteCorundum left a scratch on the surface of Apatite and. The most common scale for. Quartz Silica sand 7.

Surface Hardness Torelina Toray Plastics Toray

Komentar